Cuts on hands and lower arms represent the number one injury listed on accident statistics for the glass and metal processing industry. However, sophisticated materials as incorporated in the textreme cut-protection shirts offer a novel protection mechanism that successfully proofed itself to eliminate the primary injury risk as shown in the following case study.

As the head of safety and environment for one of the manufacturing plants of Novelis, a global market leader in rolled aluminum products, Thomas Reiner is well aware of the likelihood of cutting injuries when working with metal. At his plant thin aluminum strips are cold rolled into coils that can be used for the manufacturing of beverage cans. When fixing production breakdowns or when taking samples for quality checks, his employees are directly exposed to the danger of cuts on sharp aluminum edges. Therefore, cut protection is an absolute essential for Thomas Reiner and the safety and well-being of his employees is a top priority. To comply with the zero incident policy, Novelis invests extensively in safety measures. Reiner particularly emphasises the hazard of recoiling aluminum strips that lead to cut injuries along the lower arm area. In response, uvex developed unique cut-protection shirts (as shown in image 1), which permanently integrate the cut protection technology in the lower arm area.

The Bamboo TwinFlex® technology, previously developed by uvex for safety gloves, has proven itself to be extremely reliable. Hereby, cut resistant glass fibers with abrasion resistant polyamide ensure protection at the highest cut protection level on the outside; while soft bamboo yarn and durable Dyneema® provide ideal climate regulation and high wearing comfort on the inside. uvex safety textiles adapted this concept on their cut protection shirts by utilising cotton and other functional fibers in the shirt’s torso area and combining it with the Bamboo TwinFlex® technology along the sleeves of different lengths.

How to measure cut resistance?

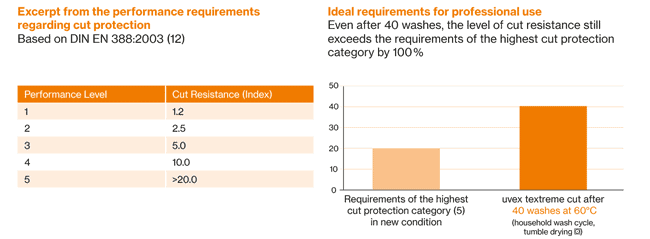

Cut resistance is tested on the basis of the safety glove requirements for EN 388. As there are no relevant standards in place yet for clothing of this kind, these models are not yet certified as personal protective equipment (PPE). Regardless, the clothing is also tested internationally to the requirements of this norm. Two samples are tested, which are cut from three different areas diagonally to the warp of the material. In the test, a rotating circular blade moves back and forth under constant pressure of five newtons and at the same rate until the blade cuts through the sample to reach the conductive base layer. The number of cycles that are required to cut through are counted and evaluated in relation to the test material. The higher the cut index, the higher the level of cut resistance.

Cut protection and washability?

Image 2 shows the success story of the cut protection material after 40 washing cycles at 60°C (regular household laundry and tumble dry). The level of cut resistance still exceeds the requirements of the highest cut resistance category by 100 percent.

Image 3 shows the samples that have been tested after 40 wash cycles at 60°C. Both pieces have been stretched to clearly show the cuts in the material. The test generated an index value of 41, which is more than twice the number of cycles required by the standard for new products to achieve the highest cut protection level in unwashed condition.

Three of the five uvex textreme cut models are suitable for industrial washing and have been tested in accordance with the EN ISO 15797 standard for industrial washing and finishing procedures of workwear. Furthermore, testing also allowed for optimisation of the cut protection models and its fit by identifying the shrinkage behavior of its individual components.

The ergonomic design empowers the uvex textreme cut line to combine highest cut protection with maximum freedom of movement and comfort.

Thomas Reiner is very pleased. Since the introduction of cut-resistant shirts, no more cut injuries have been reported at his plant. He shares how positively his employees reciprocate uvex textreme cut shirts and calls his employees voluntary commitment to protective clothing “a success story” of our product line.

Sources:

– Reiner, T. (30. April 2015). Head of the Safety and Environment department. (S. Lemnitzer, Interviewer)