If you spend most of your time on a construction site, you’ll know that hitting your head can be part of the job. Most of the time, it’s minor bumps, but sometimes it can be harder hits. Common accidents can be knocks to the side of the head, falling objects, slips, trips or falls. These can be angled impacts, and angled impacts can create a rotational motion. Each year, an estimated 60,000 work-related accidents involving head injuries are reported in Germany. Of these incidents, 1.5 per 1,000 result in a fatality due to the severity of the injury sustained. (1)

We should work to ensure adequate helmet safety when working in hazardous areas with the risk of head impacts. Taking the necessary safety precautions can help to reduce the risk of serious head injuries.

We’ve all seen the headlines about head injuries in sports: In elite rugby, football, NFL and boxing, leading to potentially severe cases, long-term issues and degenerative brain conditions caused by multiple head impacts, known as sub-concussions. Most of us risk head injury at work and in play. Some face this risk more than others, like those who work within the construction, industrial and utility sectors.

Safety helmets have been protecting people in one form or another for thousands of years. From their humble beginnings as battle armour in 2500BC to today, where their use is much more widespread, they have stood the test of time. Despite having one of the highest wearer compliance rates of all PPE products and the widespread and mostly mandatory use of hard hats, construction and industrial workers are still at risk for severe head injuries, including concussions. Our most valuable asset is our head because that is the bit that works everything else. If something happens to our head, there may be serious implications, including anything from brain injury to death.

What is rotational motion?

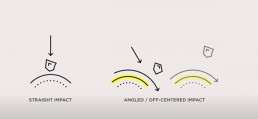

The human brain is amazing – but sensitive, especially to rotational motion. Almost all head impacts generate rotational motion, which can cause strain on the brain tissue, which may lead to minor or severe brain injuries. Concussions or even more serious brain injuries are commonly caused by rotational motion transferred to the brain. The moment your head is hit by an object or hits the ground at an angle, it can be forced to start rotating more or less, depending on the impacting object or surface. If the rotational energy generated is transferred to the brain, it can cause injury to the brain tissue or the blood vessels connected to the brain. Rotational motion results from oblique or angled impacts to the head.

Traditional safety helmets are developed and tested for straight impacts, but studies have shown that the brain is more sensitive to rotational motion (angled impacts) than linear motion (straight impacts). Rotational motion can be dangerous and result in traumatic brain injuries (TBIs). When rotational motion is involved, even impacts that might be considered light can cause concussions due to the brain’s sensitivity.

The most common type of TBI is a concussion, which accounts for up to 75% of all TBI cases. (3) (4) These injuries are far more common than you think; 50% of TBIs go undiagnosed or detected, (3) (5) while 90% of diagnosed TBIs do not involve a loss of consciousness. (6)

Statistics from US and Germany show that fall accidents in the construction industry are the most common injury leading to severe brain injuries. (3) It’s not always complex accidents that may cause traumatic brain injuries (TBIs). Statistically, there is a higher risk of suffering TBIs when working on a construction site than for industries in general. (7)

VIDEO: uvex x Mips: How the Mips® safety system works

In industries where helmets are mandatory, the greatest danger can usually be from high above. Namely, in the form of falling objects. In principle, these objects can strike the wearer’s helmet in three different ways:

- Coming vertically from above, the helmet’s centre is hit (axial impact).

- Coming vertically from above, the helmet is hit laterally – and therefore off the centre of the helmet.

- The object hits the helmet’s centre but has an oblique trajectory – it comes from the side.

The first case described here is the only one where the applied force does not lead to a rotational motion. Compared to the other two, this case is also usually the exception. Falls also pose a risk on uneven, muddy or slippery ground. If the wearer is unfortunate enough to fall, the helmet may crash or hit an obstacle such as a kerb, step or ridge. In this case, rotational motion may occur, which can be transferred to the head.

The brain is more sensitive to rotational motion than linear motion because it has shear properties similar to water or gel. When different parts of the brain move relative to each other due to rotational motion, the tissues can stretch, which can cause concussions or other brain injuries. Our brains consist mostly of water. The brain and the cerebrospinal fluid fill up most of the skull. Water is incompressible, so the brain will not move much from a straight impact. However, most angled impacts introduce a rotational motion to the head. Rotational motion to the head cause the brain to rotate inside the skull. This causes a relative movement between the skull and the brain which can cause tear of blood vessels as well as strain in the brain and can cause a TBI.

What is the Mips® safety system and how does it work?

The Mips® safety system features a low-friction layer inside the helmet designed to allow a multi-directional movement of 10-15mm on certain angled impacts. Should you have an accident and hit your head, the Mips safety system is designed to help redirect the rotational motion of certain impacts that may otherwise be transferred to your head. This is intended to help reduce the risk of brain injury. Safety helmets that are equipped with the Mips® safety system are designed to provide added safety in many accidents for the wearer.

The Mips® safety system was designed to help redirect rotational motion from the head in certain oblique impact situations in recreational and outdoor sports (climbing, mountain biking and motorbike riding) and the workplace. In practical terms, a moving layer is integrated into the safety helmet’s inside, close to the head. The low-friction layer is not rigidly fixed but is designed to move back and forth to enable the helmet to help redirect acting rotational motion from the wearer’s head using a sliding movement.

- Traditional helmets are designed and tested for straight impacts, but most impacts are angled, which can cause rotational motion to the head.

- The rotational motion can cause brain injuries.

- The Low Friction Layer is intended to help reduce the rotational motion to the head in certain angled impacts.

Everything revolves around the Mips low-friction layer. It mimics the brain’s own safety system, which allows the brain to move slightly inside the head. The Mips safety system is designed to work on the same principle. The low-friction layer is built into the helmet, making the outer parts of the helmet, the shell and the energy-absorbing layers (the “padding”) mobile so that the head can move 10–15 mm inside the helmet on impact.

VIDEO: Want to find out more? How Mips works in a safety helmet

uvex safety group has equipped selected uvex work safety helmets with the Mips® safety system in collaboration with Mips. Find out more here: https://www.uvex-safety.com/en/mips/

The Mips safety system now found in uvex safety helmets

You can find the Mips safety system in selected uvex safety hemets, currently within the pronamic alpine and pheos S-KR helmet families.

The pronamic alpine MIPS combines the technical requirements of the EN 397 and EN12492 standards in one helmet. In addition, the helmet has the size range from 51 cm to 63 cm head circumference as standard. The versatile adjustability of the head ring, generous ventilation openings and easily and quickly replaceable chin straps ensure wearing comfort. The plus in safety and functionality is complemented by multiple colour choices and extensive mountingslots for helmet accessories such as headlamps, full-vision goggles and hearing protection capsules.

Pheos S-KR is already a well-known uvex helmet that is now available with the Mips safety system. As standard, it comes in hi-vis orange, has a short cap brim and a pre-assembled 4-point chin strap, climazone ventilation and a rotary wheel for variable width adjustment. The uvex pheos S-KR MIPS is certified according to EN397.

Together with Mips, uvex works closely with safety professionals and industry experts to encourage best practices around safety equipment and awareness of head injuries, rotational injuries and how they occur. Through our partnership, will continue to evolve and push technical boundaries with the intention of improving head safety.

You can find more useful information about occupational safety in the uvex blog for experts, by experts. https://www.uvex-safety.com/blog/

References:

- https://publikationen.dguv.de/widgets/pdf/download/article/3893

- On the subject of brain sensitivity Kleiven 2003, Kleiven 2007 and https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4090913/

- The neuropathology of traumatic brain injury – https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4694720/

- Translational Research in Traumatic Brain Injury – https://www.ncbi.nlm.nih.gov/books/NBK326730/

- American Medical Society for Sports Medicine position statement: concussion in sport https://pubmed.ncbi.nlm.nih.gov/23243113/

- Concussion – https://www.ncbi.nlm.nih.gov/books/NBK537017/

- Source: DGUV 2014-2018 (Germany).