Today, the designation of origin ‘Made in Germany’ represents the considerable international reputation that products manufactured in Germany enjoy. But this was not always the case – Germany had to earn this reputation at an international level. Learn more about the history of the Made in Germany logo and find out what ‘Made in Germany’ means for the manufacture of uvex products.

Made in Germany: origin and history

‘Made in Germany’ – ironically, the story of the designation of origin begins not in Germany, but in the United Kingdom. In the 19th century, the British nation was regarded as leader of the modern industrial world. At that time, the English city of Sheffield was known for its steel working. In particular, knives from the ‘Steel City’ were of high quality and extremely popular. German manufacturers apparently wanted to emulate this fame. Amazingly similar-looking knives frequently turned up in the United Kingdom and its colonies but couldn’t match the quality of the originals. To warn consumers about the inferior quality of these rip-offs, in 1887 it was agreed as part of the Merchandise Marks Act that in future, imports from Germany had to be inscribed with the words ‘Made in Germany’.

What are the advantages of ‘Made in Germany’ products?

In just a few years, German manufacturers were able to catch up in terms of the quality of their products: soon these were not only superior to goods from the United Kingdom but could compete with goods from all over the world. And to this day, the designation of origin ‘Germany’ is a guarantee of reliably high quality.

All around the world, these properties are associated with products manufactured in Germany:

- Reliable quality

- Controlled production conditions

- High standard of workmanship

- High-quality materials

What does “Made in Germany” mean?

The Made-In-Country-Index describes how positively designation of origins from different countries are perceived. In this ranking, the Made in Germany seal is in first place. But when is a product allowed to be described as ‘Made in Germany’?

Is there an official Made in Germany seal?

The ‘Made in Germany’ logo is not a protected term, which means that it’s often difficult to find out how German a ‘Made in Germany’ product actually is. Theoretically, manufacturers can describe products as ‘Made in Germany’ even if they were largely produced abroad. However, because ‘Made in Germany’ is above all a seal that assures quality, it should not be used in a ‘misleading’ way. If a product is described as ‘Made in Germany’, it should be at least of ‘Made in Germany’ quality. How much of a product has actually been manufactured in Germany can vary. Even if a product’s individual parts or entire assemblies have been sourced abroad, it can be labelled as ‘Made in Germany’, provided that the ‘decisive manufacturing process’ that creates the particularly valued properties of the product is the result of German work carried out in Germany. Decisions on whether a ‘Made in Germany’ designation is illegal are normally made on a case-by-case basis – usually when complaints are made by consumers. When it comes to deciding whether the designation is ‘‘misleading’ or ‘not misleading’, it generally depends on the purchaser’s perception and the existing knowledge that can be presumed. For example, consumers should be aware that due to increasing globalisation, many companies are outsourcing some production steps abroad.

Made in Germany: requirements for products

The ‘Made in Germany’ seal therefore does not necessarily show that a product has been designed and manufactured entirely in Germany. Nevertheless, there are several points that are significant for the ‘Made in Germany’ designation:

- Development: Development is about designing new products. This involves various factors such as customer expectations, materials and profitability.

- Design: The appearance of a high-quality product is also significant. Design ideally combines an attractive appearance with ease of use.

- Production: The ideas from the development and design stages are implemented during production. Trained skilled personnel as well as the best machines and tools are used to ensure the result is a high-quality product.

- Quality assurance: To guarantee the quality of a finished product, it is subjected to a range of tests following production.

In order for a product to be described as ‘Made in Germany’, development, design, production and quality assurance should largely take place in Germany. Sometimes it is also required that

- the decisive production process

- the final assembly

- and a significant proportion of the value chain

are based in Germany. Here, too, the requirements are kept very vague with adjectives such as ‘decisive’ and ‘significant’.

‘Made in Germany’ products at uvex

Even if the meaning of the designation of origin ‘Made in Germany’ is not precisely defined – the development, design, production and quality assurance of the uvex products with this seal are largely carried out in Germany.

‘Made in uvex’ quality: what’s important to uvex?

Due to globalisation, products are increasingly being made abroad at very cheap prices – often under inhumane conditions and with serious implications for the environment, which is why uvex continues to rely on Germany as a production location.

Advantages of uvex ‘Made in Germany’ products include:

- High availability: If production is dependent on global supply chains, problems can quickly arise when international sources of supply become scarce, resulting in delayed deliveries and failed deals with customers. If the production site is located in Germany, these complications are often eliminated – even in crisis situations.

- Short transport routes: Transport within Germany means shorter distances and thus lower energy consumption and fewer CO2 Product delivery can also be faster and more flexible.

- Maximum quality: Products manufactured in Germany represent maximum quality. This means that with uvex you are investing in sustainable and durable protective equipment that you can rely on one hundred percent. Products that last longer mean lower costs, fewer raw materials and less waste, which in turn promotes sustainability and environmental protection.

- Sustainability: Production in Germany means that strict standards are complied with in the manufacture of our products. For example, this ensures that workers in our production facilities receive fair wages and that work processes are designed to be as environmentally friendly and sustainable as possible. In addition, uvex is committed to conserving resources: by reducing the exchange of pollutants, raw material consumption and noise pollution in our production processes, we help respect the environment and make our products more sustainable.

Where in Germany does uvex manufacture its products?

uvex manufactures two high-quality product ranges in Germany – our gloves and our safety eyewear.

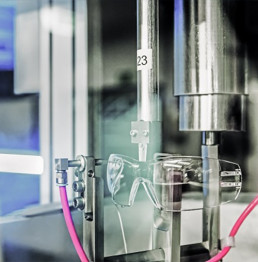

Safety eyewear from Fürth: The city of Fürth is contiguous with Nuremberg, the second largest city in Bavaria. It is the location of the uvex headquarters – and also where, in our unique competence centre for protective eyewear, the uvex safety group produces our high-quality safety eyewear, including spectacles, goggles, prescription safety spectacles and laser protection eyewear.

Safety gloves from Lüneburg: Safety gloves are among the most important items when it comes to personal protective equipment. To ensure you are kept as safe as possible, most of our safety gloves are designed and manufactured in our hand protection competence and technology centre in the North German town of Lüneburg. Sustainability is particularly important to us: our safety gloves are the only ones in Europe to be certified in accordance with the international environmental management standard ISO 14001. In this video, you can find out more about how uvex safety gloves are made.

Discover ‘made in uvex’ quality!

‘Made in uvex’ is our hallmark of quality. For us, quality is an attitude and a business model that impacts the whole production process:

- Added value: We are present at every step of production and guarantee quality.

- Superior quality: Right from the development stage, uvex products are subjected to in-house tests and exceed the specified safety standards.

- Locations: The employees at our German, European and overseas locations are trained to a high standard because our expert knowledge is passed on.

- Sustainability: uvex is careful to use resources sparingly. This means that the company reduces pollutant emissions, keeps consumption as low as possible and reduces noise pollution. In turn, the saved costs help keep uvex quality standards high.

- Independence: Thanks to the healthy development of the family business, we handle investments ourselves and are therefore independent.

- Tools: uvex develops its own tools, thus guaranteeing quality across the board.

Since the company was founded in 1926, uvex has been synonymous with high-quality protective equipment made in Germany. And you can still benefit today from our technical know-how, our enthusiasm for first-class products and individual solutions for employees. Find the perfect PPE for your workplace or company now!