Every year, over 100,000 workers are injured on construction sites in Germany. That’s more than 10% of the people working in this sector across the country! The risk of injury on a construction site, as you might guess from these figures, is extremely high. Personal protective equipment that meets the requirements of the construction industry is therefore essential. Firm footing – whether on wet, uneven or dry ground – is particularly important for safe working on the construction site. That’s why we’ve expanded our range for the construction sector with the uvex 3 safety shoe. Like all our safety products for the construction industry, this new product group offers the necessary durability and stability as well as maximum comfort. In this blog article, you’ll discover all the special features of the uvex 3 and why this safety shoe is the perfect solution for the construction sector.

1. uvex bionom x: guided by biomechanics

Heavy-duty applications involve external influences that place extensive demands on the shoe, its durability and stability. Accordingly, workers in the heavy equipment engineering sector, on construction sites or in structural and civil engineering, for example, require enhanced foot protection. However, they often complain that it feels as if their feet have to ‘work against’ their footwear with every step they take. Words such as heavy, clunky and stiff are often used. The reason safety shoes feel like this is that during the design process, manufacturers focus mainly on the shoes’ protective function and not on the natural movement of a person’s feet as they walk.

The result: the wearer soon experiences symptoms of fatigue and even pain as a consequence of the overloading and incorrect loading of the feet. However, the feet – and thus the entire body – can only perform at their best if the essential biomechanical functionality of the body is aligned with the functionality of the footwear.

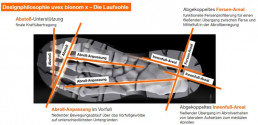

The uvex bionom x principle takes care of this, making it more than just a principle – you could even call it a design philosophy. It was developed by the uvex safety group under the leadership of Australian biomechanics expert Dr Caleb Wegener. The new shoe model uvex 3 is an impressive example of how body, footwear and environment can combine to form a harmonious whole. For example, the sole of this safety shoe has ergonomic tread grooves, which adapt to the anatomical structure of the foot. These functional grooves ensure that the sole is extremely flexible and slip-resistant. There are also several applications in the upper that take into account the ergonomic features of the foot: seams are minimised and positioned so that they will not press on tendons or nerves, while specific compression and expansion zones ensure increased comfort from heel strike to toe-off.

At the same time, the shoe is particularly robust and provides excellent protection against the extreme demands of heavy-duty applications. For example, the tread of the slip-resistant safety shoe has deep grooves that ensure good grip even on wet and slippery surfaces. To make sure this grip is maintained throughout the working day, the special shape of the tread grooves means that no dirt accumulates on the soles, because dirty shoe soles seriously compromise safety.

2. uvex i-PUREnrj: stabilising shock absorption with energy return

Feet must perform at their best with every single step, because the body weight they carry is multiplied by the kinetic energy generated as they walk. If a person’s work also involves heavy lifting and carrying, pain may be felt not only in the feet, but also along the kinetic chain – in the knees, hips and the back, to give just a few examples. This illustrates how important good footwear is as a basis for health and the entire musculoskeletal system.

That’s why safety shoes need cushioning. On the uvex 3 work shoe, the innovative polyurethane sole with uvex i-PUREnrj technology can absorb up to 44 joules of impact energy on the heel, 2.8 times more than conventional polyurethane soles and 2.2 times more than required by the EN ISO 20345:2011 standard.

A special feature of the uvex 3 is the energy return across the entire sole. It supports the gait movement of the foot with up to 65 per cent energy return in the heel area and up to 68 per cent energy return in the forefoot area. This gives momentum to every step and prevents premature foot fatigue. “Easy going” instead of “hard work” – for the long term. The uvex i-PUREnrj midsole with higher shock absorption has already proved in the models of the uvex 1 G2 series that, even after 1,000 kilometres walked, it is at least 29 per cent better than standard polyurethane soles.

However, shoes with good energy return often feel a little unstable because the soles are relatively soft to allow them to cushion the wearer’s feet. To help stabilise the foot, the uvex 3 has a foam heel basket. This in turn reduces the risk of injury, for example twisting an ankle.

3. uvex waterstop and uvex climazone: keeping feet dry

Few things are as unpleasant as wet feet. If shoes get soaked easily and the material absorbs moisture, they’ll really start to weigh you down. That’s why, when working in wet environments, safety shoes must protect against water getting in. This is where uvex waterstop technology makes a real difference: the specially tanned leather of the uvex 3 keeps feet dry for four times longer than required by the standard for safety shoes.

An uncomfortably wet feeling can also result from the feet sweating excessively in safety shoes that aren’t breathable enough. During an active working day, an amount of moisture equivalent of an entire glass of water can be accumulated! Not with the uvex 3: the innovative uvex climazone foot climate management system wicks away perspiration to the outside, ensuring maximum comfort and safety shoes that always feel pleasant to wear. 26 perforations in the ankle area, on the outside and inside of the shoe, also support the ventilation of the foot, both a clever design element and a nod to the year in which uvex was founded – 1926.

4. uvex lacelock and uvex anklepro: stability and ankle protection

A clever lacing system also plays an important role in ensuring that the foot remains stable even under a heavy load. That’s why uvex safety developed the uvex lacelock special lacing eyelets. These are attached on the side, so that tying them provides an additional stabilising effect for the ankle. They also securely lock the laces. This effectively eliminates the risk of tripping due to open laces.

Next to the toes, the ankle is probably the most shock-prone area of the feet. The skin there is very thin – and the impact of force is particularly painful. This is where you can rely on uvex anklepro. The ankle protection on the uvex 3 absorbs shocks with the help of a particularly energy-absorbing foam and at the same time ensures optimum freedom of movement in the ankle region.

5. Sustainable safety shoes: hazardous substances, no thank you – recycling, yes please

Another hallmark of good foot protection: safety shoes that are free from hazardous substances. Substances that are on the uvex banned hazardous substances list are therefore also nowhere to be found in the manufacture of the uvex 3. However, uvex safety takes its mission of ‘protecting people’ a crucial step further. Because this mission involves responsibility not only towards the individual, but also towards society and especially the environment, uvex safety places great emphasis on sustainability when developing all its products. On the uvex 3, the insole is made of 100 per cent recycled fibres and foam.

This is a good idea because this component of the safety shoe is constantly in direct contact with the foot and subject to high levels of wear. Insoles should therefore be replaced regularly. If they’re made of recycled material, this makes them an important part of the fight to reduce waste more effectively.

Interested in foot protection that’s safe, lightweight and comfortable and comes in a great sporty design? Find out more about the new uvex 3 safety shoe.