Unter Ergonomie wird, im Zusammenhang mit Arbeit, die Optimierung der Arbeitsbedingungen, des Arbeitsablaufes und des Arbeitsraumes verstanden, um den Menschen vor Ermüdung oder gar Schäden zu schützen.

In relation to work, the term ergonomics is understood to cover optimising working conditions, operational processes and the workspace in order to protect employees from fatigue and dangers.

In relation to work, the term ergonomics is understood to cover optimising working conditions, operational processes and the workspace in order to protect employees from fatigue and dangers.

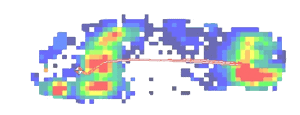

The Federal Ministry for Labour and Social Affairs cites problems relating to the musculoskeletal system as a common cause of work incapacity and early retirement (due to reduced ability to work). The majority of problems relate to the joints and spine. Among other factors, the occurrence of these illnesses is directly linked to the type of movement, energy expended, loads, posture, vibration and fatigue. To combat this, in the first instance it is necessary to adjust work processes, workspaces and conditions – all this falls under the general umbrella of ergonomics in the workplace. In working environments where safety and protective clothing must be worn, a further factor that has not thus far been paid much attention is safety footwear, which has a great influence on the body, movement and load. Studies* have shown that in addition to plantar pressure distribution, the construction and design of shoes also affects the body from joint angles in the legs all the way up to upper body posture. Accordingly, it is possible to alter the muscle activation and the strain that is placed on the different areas.

Insufficient support and pressure points can cause foot pain. Given the connection between bones, joints, tendons, ligaments and muscles, the source of commonly occurring problems in the spinal area can often be found in the feet. Pressure distribution across the foot and joint angles is influenced by the individual foot shape and position as well as walking and rolling movements. Other potential negative factors include incorrect foot positioning, such as hollow, flat and splay foot. These malpositions already cause a change in pressure distribution when standing. Other differences that arise in joint angle positioning can also lead to an increase or decrease in muscle and joint pressure by shifting the leverage and points at which force is applied.

Insufficient support and pressure points can cause foot pain. Given the connection between bones, joints, tendons, ligaments and muscles, the source of commonly occurring problems in the spinal area can often be found in the feet. Pressure distribution across the foot and joint angles is influenced by the individual foot shape and position as well as walking and rolling movements. Other potential negative factors include incorrect foot positioning, such as hollow, flat and splay foot. These malpositions already cause a change in pressure distribution when standing. Other differences that arise in joint angle positioning can also lead to an increase or decrease in muscle and joint pressure by shifting the leverage and points at which force is applied.

Which components of a safety shoe can influence the effects?

Sole construction

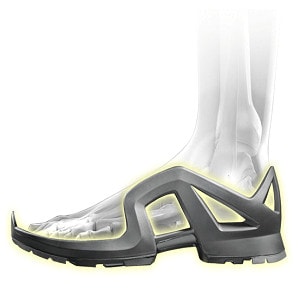

The sole construction can influence the parameters of pressure distribution and joint angles mentioned above. The shape of the sole affects the area on which the force has an impact and therefore also the pressure distribution. In the same way, joint positions that are adopted on contact with the ground can also be adjusted. This applies both when the foot is placed down and during the rolling movement when walking. Additional supporting or guiding elements are commonly incorporated into the sole structure. These serve to correct foot malalignments and control movement in order to ultimately prevent injury and strain damage. For example, to reduce overpronation of the foot and prevent adverse strain through this movement, medial supports are often attached to the inner side of the foot. Special torsion reinforcements are quite common in the metatarsal area as they reduce the ability of the front and back of the foot to rotate, thereby preventing injury.

Ergonomic sole design also features in safety footwear in the uvex 1 product range. The sole has an optimised mid-foot torsion stability, flexible grooves to increase movement and a pivot point to support rotation in the front of foot. Overall, the design of the outsole supports the natural movement of the foot from the heel along the outer mid-foot all the way to the big toe.

Shock absorption

Without additional shock-absorbing elements, the body must, to a certain extent, absorb the forces that occur when walking itself. Consequently, the forces are distributed to areas of natural subcutaneous fat. The level of absorption is increased through adjustment of joints by bending more strongly when there is greater pressure. The higher the shock absorption in the shoe, the lower the energy requirements of an individual’s muscles to process the corresponding forces. This also applies to strain on joints and all the way up the spine. The additional material increases the surface area and thereby reduces the pressure on zones that are placed under extreme load. The type of material and shape of the sole determine the level of shock absorption and materials of different densities are applied. A greater level of shock absorption is achieved through lower density materials and a higher number of sole layers. EVA materials are often used in sports footwear, with the addition of gel or air pockets in some cases. Depending on the area of application, PUR or rubber soles are often used for safety footwear. The uvex 1 safety footwear range has a multi-layer sole system, with the mid-sole made from a PUR material with low density to provide optimum shock absorption.structure.

Without additional shock-absorbing elements, the body must, to a certain extent, absorb the forces that occur when walking itself. Consequently, the forces are distributed to areas of natural subcutaneous fat. The level of absorption is increased through adjustment of joints by bending more strongly when there is greater pressure. The higher the shock absorption in the shoe, the lower the energy requirements of an individual’s muscles to process the corresponding forces. This also applies to strain on joints and all the way up the spine. The additional material increases the surface area and thereby reduces the pressure on zones that are placed under extreme load. The type of material and shape of the sole determine the level of shock absorption and materials of different densities are applied. A greater level of shock absorption is achieved through lower density materials and a higher number of sole layers. EVA materials are often used in sports footwear, with the addition of gel or air pockets in some cases. Depending on the area of application, PUR or rubber soles are often used for safety footwear. The uvex 1 safety footwear range has a multi-layer sole system, with the mid-sole made from a PUR material with low density to provide optimum shock absorption.structure.

Shaft

The structure and material of a safety footwear shaft have a major impact on the comfort of the wearer. In addition to fit and breathability, the supporting elements are also critical. Breathable materials are used to create a climate inside the shoe that is as comfortable as possible for the wearer.  The aim is to wick away moisture coming from the foot and ensure good air circulation. For the best-possible result, this should occur across all layers of the shaft. Wearer comfort also comprises the prevention of friction and pressure points. Ways of achieving this include integrating a padded tongue or collar in the shoe, so that there are no hard edges or rough transitions. The uvex 1 safety footwear range includes a special construction to provide a certain amount of stability for the foot. There is an extension to the outsole which goes beyond the shaft and in this way provides reinforcement. The sole therefore supports the mid-foot and heel, which protects against incorrect strain and going over on the joint.

The aim is to wick away moisture coming from the foot and ensure good air circulation. For the best-possible result, this should occur across all layers of the shaft. Wearer comfort also comprises the prevention of friction and pressure points. Ways of achieving this include integrating a padded tongue or collar in the shoe, so that there are no hard edges or rough transitions. The uvex 1 safety footwear range includes a special construction to provide a certain amount of stability for the foot. There is an extension to the outsole which goes beyond the shaft and in this way provides reinforcement. The sole therefore supports the mid-foot and heel, which protects against incorrect strain and going over on the joint.

Fit

A further important factor that influences the decision for or against a particular safety footwear model is fit. The individual shape of the foot again plays a role. In addition to the particular features and foot malalignments, this is above all determined by the length and width of an individual’s foot. The length of the foot is generally always catered for by standard shoe sizes. Some safety footwear manufacturers offer multiple width systems with the aim of adapting the interior of shoes to different foot widths. The selection is based on measuring the circumference of the ball of the foot at the height of the base toe joints and the width of the foot measured from the metatarsophalangeal joint (at the base of the big toe) to the basal joint of the little toe. A range of different features, such as insoles that reduce or expand the inside of a shoe, are added to implement this system. Ultimately, the multiple width system makes it possible to cater for a broader range of different foot shapes.

Overall, there are many options for incorporating ergonomics in safety footwear. As has been detailed above, safety footwear ranges today already include many ergonomic features. Nonetheless, constant innovation is taking place to ensure the best-possible protection and support is provided to wearers in their everyday working environment.

* U.Noll. 2011, Dissertation: Möglichkeiten der Prävention von Erkrankungen am Stutz- und Bewegungsapparat durch das Sicherheitsschuhwerk bei Mitarbeitern der Automobilindustrie (Options for preventing problems relating to the musculoskeletal system through safety footwear worn by employees in the automotive industry)

Please do not hesitate to contact us with any questions on the right equipment in the work place and how to prevent damage and injuries.

Please email expertenblog@uvex.de and we will be happy to help.

Great Post

Great piece of Information

Web development company in Kochi

good instruction by the way, Thanks for sharing this!

very interesting.

Amazing blog! I really like the way you explained such information. And blog is really helpful for us.