Where physical work is involved, PPE is often essential. For millions of employees in Germany, safety shoes, protective eyewear, and more are part of everyday work life. Employers are legally obliged to invest in their workers’ protection. How important high-quality PPE is – for both employees and employers – is illustrated by the case studies in this article.

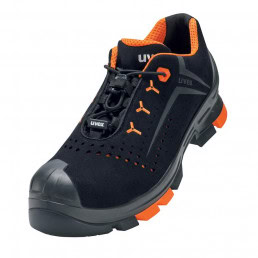

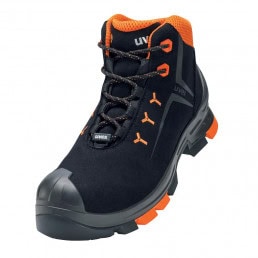

The calculation is quite simple – and yet highly impressive. A globally renowned car manufacturer saves over €1 million annually because it now provides its employees with uvex safety shoes. And there’s even more potential for savings, as this seven-figure sum only applies to one of several production sites – in this case, located in England. The key factor here: service life. In other words, the length of time PPE can be used without significant wear and tear.

With another manufacturer’s safety shoe, that used to be about six months. Then the automaker switched to the model uvex 2 – resulting in a lifespan of 18 to 24 months, cost savings, superior comfort and protection for employees, and greater sustainability. After all, hard-working people naturally feel better in high-quality shoes, and far less waste is generated when shoes don’t need to be discarded every six months.

This is just one of many success stories that German PPE manufacturer uvex shares with industrial companies worldwide. But it clearly demonstrates how crucial it is to focus on high quality when it comes to personal protective equipment. Alongside the use of bio-based materials and recycled content in products ranging from helmets to shoes, low-emission production in uvex’s own facilities, and strict supply chain control, one key pillar of uvex’s sustainability strategy is this: premium products. Sustainable means long-lasting.

uvex Bamboo TwinFlex D xg impresses with exceptional durability

Another prime example of this approach is the uvex Bamboo TwinFlex D xg, the bestseller among cut protection gloves. A heavy-duty product test conducted with a tire manufacturer revealed that uvex’s glove lasted eight days longer than comparable products from other brands. And that’s no coincidence: valuable user feedback flows directly into uvex’s product development. Thanks to a reinforced thumb crotch and high-quality Xtra-Grip polymer coating, the Bamboo TwinFlex® D xg is exceptionally durable.

The gloves are made in Lüneburg (northern Germany), the safety glasses in Fürth (southern Germany), and the safety shoes in Italy. The traditional German PPE manufacturer relies on its own facilities with full control over every production step. uvex calls this “Made in uvex” – a true quality mark that is now gaining traction in the USA.

There uvex subsidiary HexArmor helped Valmet solve the problem of safety glasses fogging up too quickly. Previously, employees had to replace their glasses every three days. Now, HexArmor models with anti-fog coating last three months, cutting costs by over 80 percent. “Once we ordered the glasses, we couldn’t give them out fast enough,” said one Valmet employee.

“Everyone wanted a pair. They are comfortable, and the design is stylish while still offering complete protection. Employees are happy to wear PPE now.”

Maximum protection, superior comfort, long service life – and thus reduced costs and waste: uvex’s goal is to create high-quality PPE solutions that meet all these requirements. This benefits customers, their employees, and the environment. The calculation is simple: Buy cheap, buy twice.