Organic food products are part of every supermarket’s standard range now. The focus in this regard is on untreated fruit and vegetables. This is because foodstuffs that have been treated with pesticides can be detrimental to the health of end customers when they are consumed and the health of employees when they are handled. In this blog, we go deeper into what pesticides are and how you can protect yourself when handling them.

What are pesticides?

The word “pesticides” comes from the English “pests” and are plant protection products. These protect plants or plant products from harmful organisms and diseases. In addition, pesticides are used to regulate plant growth. In some cases, pesticides are extremely toxic chemicals in high concentrations.

What pesticides are there?

Pesticides were developed to protect plants from any risk. These are divided into three groups:

- Herbicides

- Insecticides

- Fungicides

Herbicides – protection against unwanted plants

Herbicide is another word for weed killer and is therefore the most well-known and most commonly used pesticide. Herbicides are used to inhibit unwanted plants by creating conditions that result in them dying. Herbicides cause accelerated growth, whereby the respective plant cannot take in enough nutrients and consequently dies. Some weed killers have a caustic effect or impair a plant’s photosynthesis process so that the plant stops growing.

Insecticides – protection against destructive insects

Insecticides are pesticides formulated to kill, repel and inhibit insects. They prevent insects such as aphids, caterpillars and beetles from negatively impacting on the quality and yield of a crop.

Fungicides – protection against fungi

Fungicides are substances that kill fungi or inhibit their growth. The active substances in fungicides affect the metabolism of fungi and thereby control growth or even result in fungi dying.

The possible undesirable side effects are just as varied as the compositions of various pesticides. Pesticides not only damage plants, insects and fungi, but can have a detrimental impact on human health – the adverse effects of pesticides include diseases such as cancer, infertility and a weakened immune system.

Use of pesticides – pesticides in the agricultural sector

People who come into contact with pesticides typically work in the agricultural sector. These include people who use plant protection products directly as well as those who carry out follow-up work on treated areas or deal with treated products. The risk of being exposed to pesticides in the course of such work is very high.

In industrial countries, pesticides are largely distributed across fields with modern technology so that direct contact with the substances is minimised. However, there are situations in which special protective equipment is necessary, such as when decanting, spreading or reworking pesticides.

Plant protection legislation – protective equipment for using plant protection products

Plant protection legislation sets out strict rules that stipulate how pesticides are to be used safely, appropriately and in accordance with their intended purpose. According to the German Plant Protection Act (PflSchG), plant protection products must not have any harmful effects on human health. Accordingly, a risk assessment is carried out together with the Federal Office of Consumer Protection and Food Safety (BVL) when pesticides are approved. Regulations governing the use of pesticides, such as the protective equipment required, are set out and stipulated as part of this process. The respective personal protective equipment is indicated in the conditions of use section of the safety data sheet for the pesticide.

Furthermore, BVL provides information on approved plant protection products and what needs to be considered when using pesticides. Depending on the pesticide to be used, PPE consists of the following elements:

- Protective suit

- Gloves

- Head protection

- Safety Eyewear

- Respiratory protection

- Rubber apron

- Foot protection

The requirements regarding personal protective equipment for the use of plant protection products are described in the BVL guidelines “Personal protective equipment for handling plant protection products”. In addition, the BVL has compiled a list of certified PPE for protection against pesticides, which is regularly updated and is designed to make purchasing the correct personal protective equipment an easier process.

PPE for plant protection products – relevant standards

If, due to the risk assessment, a protective suit for protection against plant protection products is required when handling a pesticide, the suit must comply with at least one of the following standards according to BVL guidelines:

- Level C3 protective clothing in accordance with EN ISO 27065 “Protective clothing – performance requirements for protective clothing worn by operators handling liquid pesticide products as well as protective clothing worn by re-entry workers”.

- Type 3 or 4 protective clothing in accordance with EN 14605 “Protective clothing against liquid chemicals – Performance requirements for full-body protective clothing with liquid-tight (Type 3) or spray-tight (Type 4) connections between different parts of the clothing”.

EN ISO 27065

Standard EN ISO 27065 consists of three levels, C1, C2 and C3, whereby C3 is the highest protection level.

- C1 and C2 are suitable for follow-up work, with C2 also being suitable for use with diluted plant protection products. The majority of protective clothing that meets the requirements of these levels is reusable.

- C3 is suitable for use with diluted plant protection products as well as concentrated pesticides with which the respective user may come into contact during the mixing process.

The suitability test as part of standard EN ISO 27065 considers the material and seams of the protective suits in question. The test classifies the protective clothing based on physical and chemical material properties. The tests are carried out under controlled laboratory conditions using defined test substances.

Protective clothing certified in accordance with EN ISO 27065 can be labelled with the pictogram of a conical flask with two leaves. Alongside the standard, the respective class is indicated on the pictogram.

Type 3 or 4 protective clothing in accordance with EN 14605

To ensure optimal protection for individual hazardous areas, the European Union has defined harmonised standards for different protection classes (types) for chemical protection.

Following a successful jet test result in accordance with EN 14605, Type 3 – liquid-tight protective clothing – is defined as: “protection against a strong, directed jet of liquid”.

Type 4 is also a liquid-tight suit but provides protection against liquids that are not pressurised.

You can find more information on the standards and guidelines for full-body protective clothing in our blog post.

ISO 18889

ISO 18889 is a standard for protective gloves for users of plant protection products and comprises three levels GR, G1 and G2 – with G2 being the highest level of protection.

- GR: Partially coated protective gloves provide protection from dried spray coating during follow-up work.

- G1: Fully coated protective gloves for handling ready-to-use crop protection products.

- G2: Fully coated protective gloves for handling concentrated pesticides.

As an alternative to ISO 18889, protective gloves that meet the requirements of DIN EN ISO 374-1 and / or DIN EN 388 are suitable.

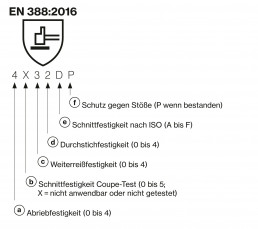

DIN EN 388

DIN EN 388 is a standard for protective gloves against mechanical risks. It contains various test procedures with which the mechanical performance of gloves can be compared. The focus here is on the following 6 performance levels.

- Abrasion resistance: To test the abrasion resistance of the protective glove, the material is subjected to abrasive paper under pressure. The number of cycles required to grind a hole in the material serves as the material is used as a reference. (Highest performance level 4 = 8,000 cycles).

- Cut resistance using the Coupe test: To test the cut resistance of a protective glove, a rotating circular knife is used which cuts through the glove material at constant speed and constant force. The reference value is a comparison with a reference material and a resulting index. (Highest performance level 5 = index 20)

- Tear resistance: To test the tear resistance, the material of the protective glove is first cut into. The reference value is the force required to tear the material. (Highest performance level 4 = 75 Newton)

- Puncture resistance: To test the puncture resistance, the material to be tested is pierced with a nail (specified dimension). The force applied for this serves as a reference value.

- Cut resistance according to TDM: The application of the test method according to ISO 13997 is relevant for materials which blunt the rotating circular knife in the Coupe test (see above). The force required to cut through a material at a defined distance (20 mm) is measured (highest power level F = 30 Newton).

- Additional protection against impact: Gloves with the performance level “P” at the end provide specific impact absorption.

DIN EN ISO 374-1

DIN EN ISO 374-1 is a standard for protective gloves against hazardous chemicals and microorganisms.

and microorganisms. Chemical protective gloves

must meet these requirements. A distinction is made between the permeation resistance of type A, type B and type C:

Do you regularly come into contact with pesticides and are thereby exposed to the risks that they pose? We would love to hear about your experiences of handling plant protection products. Are you already adequately protected? We’re happy to advise you in detail on the best personal protective equipment for your workplace.