Compliance with a series of regulations and directives is required for the sale and distribution of personal protective equipment (PPE) such as safety shoes, safety gloves and many other items of protective clothing within the European Union. In this blog post, we take a closer look at the legal requirements for the sale of PPE in the safety shoe category.

PPE Regulation EU 2016/425

The European standards for safety shoes have been developed and published on the basis of the first EU Directive 89/686/EEC for the sale and distribution of personal protective equipment in the countries of the EU. At country level, this directive has been transposed into national law in numerous, country-specific laws. In Germany, this concerned in particular the Occupational Safety and Health Act (ArbSG) and the Product Safety Act (ProdSG) as well as a series of further laws and regulations. The Directive was adopted in 1989, in order to have uniform legal requirements in all EU member states. The goal was to create a European single market for personal protective equipment (PPE).

The directive was first superseded in 2016 by the PPE Regulation EU 2016/425, which has been in force since April 2018 following a transition period. The aim of the revision was better protection for PPE users and a reform of the conformity assessment processes. This regulation is directly applicable in all EU countries and does not need to be transposed into national law first.

The European standards have been harmonised through their publication in the Official Journal of the European Union and subsequently published by the national standardisation bodies with identical content. National standards that contradicted the concept of the European single market were withdrawn at the same time.

The three categories of PPE

European Union law recognises three categories of personal protective equipment:

- Category 1: Minor risks in the workplace

- Category 2: Standard protective clothing for industrial use

- Category 3: Protection against lethal hazards and irreversible damage

Category 1

Category 1 includes simple types of PPE, for which the user can assess the effectiveness against minor risks themselves. For example, these could be safety gloves for light gardening tasks.

Category 2

Category 2 includes all PPE products that do not fall into either category 1 or category 3. Standard safety shoes in protective classes S1, S1 P, S2, S3, S4 and S5 are also included in this category, for example. We explain which particular regulations and directives apply to PPE safety shoes in the next paragraph.

Category 3

PPE in category 3 is intended to protect against lethal hazards and irreversible damage. This includes fall protection or respiratory protection with filters, for example.

Legal requirements for the safety shoe category

Safety shoes must be subjected to a type examination (certification) before they are placed on the market. The type examination for safety shoes is carried out in an accredited test laboratory. These notified bodies are appointed by the EU member states and regularly checked for their suitability and equipment in order to continue to be allowed to carry out the type examination.

Manufacturers require a Declaration of Conformity based on the type examination certificate to sell and distribute PPE in the safety shoe category in all European Union countries. The type examination certificate is issued if the tested safety shoe meets the requirements of a harmonised standard, as there is then a presumption of conformity with the requirements of the EU Regulation. Only with the type examination certificate and the declaration of conformity may the manufacturer sell and distribute their product within the EU.

The following harmonised standards for PPE safety shoes apply:

- EN ISO 20345:2011: Personal protective equipment – Safety footwear

- EN ISO 20346:2014: Personal protective equipment – Protective footwear

- EN ISO 20347:2012: Personal protective equipment – Occupational footwear

- EN ISO 20349-1:2017: Personal protective equipment – Footwear protecting against risks in foundries and welding – Part 1: Requirements and test methods for protection against risks in foundries

- EN ISO 20349-2:2017: Personal protective equipment – Footwear protecting against risks in foundries and welding – Part 2: Requirements and test methods for protection against risks in welding and allied processes

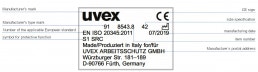

Safety shoe labelling

Every pair of PPE safety shoes must be labelled in accordance with the applicable rules and accompanied by user information. Safety shoes are labelled as follows:

The PPE safety shoe user information details the certifications, exclusions of use, etc. In general, a distinction is made between basic and additional requirements for safety shoes.

Basic requirements are obligatory for all safety shoes and, in particular, include qualitative specifications for the materials used such as protective toe caps, the design and the production technology.

A further requirement is the slip-resistant properties of the PPE safety shoes. For these, minimum coefficient of friction requirements must be met on specified combinations of floorings and lubricants. Shoes are rated as SRA, SRB or SRC depending on the type of flooring on which they are tested.

SRA slip resistance rating

For this rating, slip resistance is tested on a ceramic tile floor with a sodium lauryl sulphate solution NaLS. Forward heel slip, for which the coefficient of friction must be no less than 0.28 and forward flat slip, for which the coefficient of friction must be no less than 0.32 are both tested here.

SRB slip resistance rating

For this rating, slip resistance is tested on a steel floor with a glycerine solution. Forward heel slip, for which the coefficient of friction must be no less than 0.13 and forward flat slip, for which the coefficient of friction must be no less than 0.18 are both tested here.

SRC slip resistance rating

For this rating, slip resistance is tested both on a ceramic tile floor with sodium lauryl sulphate solution and on a steel floor with glycerine solution. The SRA and SRB test conditions for forward heel slip and forward flat slip are also used in this test.

If PPE safety shoes require additional safety features besides the basic requirements, the additional requirements must be met. The safety shoe standard currently defines 13 different additional requirements, each of which is represented by a symbol on the label:

| Symbol | Description |

| P | Penetration resistance |

| C | Conductive footwear |

| A | Anti-static footwear |

| HI | Heat insulation |

| CI | Cold insulation |

| E | Energy absorption around heel |

| WR | Water-resistant |

| M | Metatarsal protection |

| AN | Ankle protection |

| CR | Cut-resistant upper |

| WRU | Water-resistant upper (outer shoe material) |

| HRO | Heat-resistant outsole |

| FO | Fuel/oil resistance |

As the symbols on the label on the shoe can become quite confusing, the standard includes abbreviations that represent frequently used combinations of additional requirements. In addition to the basic requirements (abbreviated as SB), these are the abbreviations commonly referred to as protection classes for safety shoes S1, S2, S3, S4 and S5 with the properties assigned according to the following tables:

For all shoes

| Abbreviation | Description |

| SB | Basic requirements |

For shoes made of leather or other materials

| Abbreviation | Description |

| S1 | Basic requirements + closed heel area + anti-static properties (A) + energy absorption around heel (E) + fuel/oil resistance (FO) |

| S2 | As for S1, plus water penetration and absorption of the outer shoe material |

| S3 | As for S2, plus penetration resistance (P) + treaded sole |

For rubber shoes or entirely moulded polymer footwear

| Abbreviation | Description |

| S4 | Basic requirements + closed heel area + anti-static properties (A) + energy absorption around heel (E) + fuel/oil resistance (FO) |

| S5 | As for S4, plus penetration resistance (P) + treaded sole |

For hybrid shoes

Hybrid shoes are shoes that are made entirely of a polymer material in the lower part while the shoe upper is made of another material, e.g. leather

| Abbreviation | Description |

| SBH | Basic requirements |

Further additional requirements that are not included in the descriptions of the abbreviations are identified by their symbol in addition to the abbreviation. For example, an S1 low shoe that is also penetration-resistant is labelled S1 P.

Would you like to read more about PPE regulations etc.? Then be sure to check out our blog post “PPE Regulation – directives & safety regulations”. If you have further questions about the regulations and directives for the sale and distribution of PPE safety shoes and other items of uvex protective clothing, leave your comments and questions in the comments section below or get in touch with us directly using our contact form.

I read this post, your post is so nice and very informative post, thanks for sharing this post!