Innovative features "made by uvex"

Safety gloves that offer more than just protection.

From high-tech yarn to the uXT coating

We develop safety gloves that can do more than provide reliable protection. They have exclusive features ranging from the patented Bamboo TwinFlex® yarn to 3D ErgoFlex Technology and the highest possible health standards. Only available from uvex.

uvex represents improved wearer comfort, improved functionality, improved cost efficiency

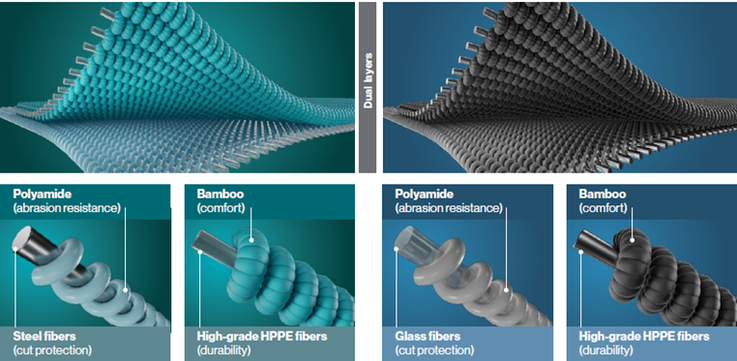

Bamboo TwinFlex® Technology

Bamboo-fibre-based cut protection is only available from us. No other gloves are as comfortable.

Anyone who has ever worn uvex safety gloves will never want to wear any others. The patented high-tech Bamboo TwinFlex® yarn creates unique wearer comfort: Unlike gloves made from synthetic fibres, the silky-soft bamboo viscose material feels particularly natural. It feels more like a comfy tennis sock than football jersey made of synthetic materials. Anyone who wears gloves eight hours a day at work will appreciate this feel.

Patented high-tech Bamboo TwinFlex® yarn

for protection without sweating

The breathable natural fibres absorb up to six times more moisture and therefore prevent your hands from sweating, even during longer periods of use. At the same time, Bamboo TwinFlex® Technology offers reliable protection while you work: uvex is the only manufacturer in the world to combine natural comfort fibres with safe cut protection. Cut protection combined with sweat protection, so to speak. Only available from uvex.

Unique combination of materials

Maximum protection and wearing comfort

thanks to double-layered material

Durability and breathability

thanks to high-quality HPPE fibres and bamboo

Abrasion resistance and cut protection

thanks to Polyamide and and Steel fibres

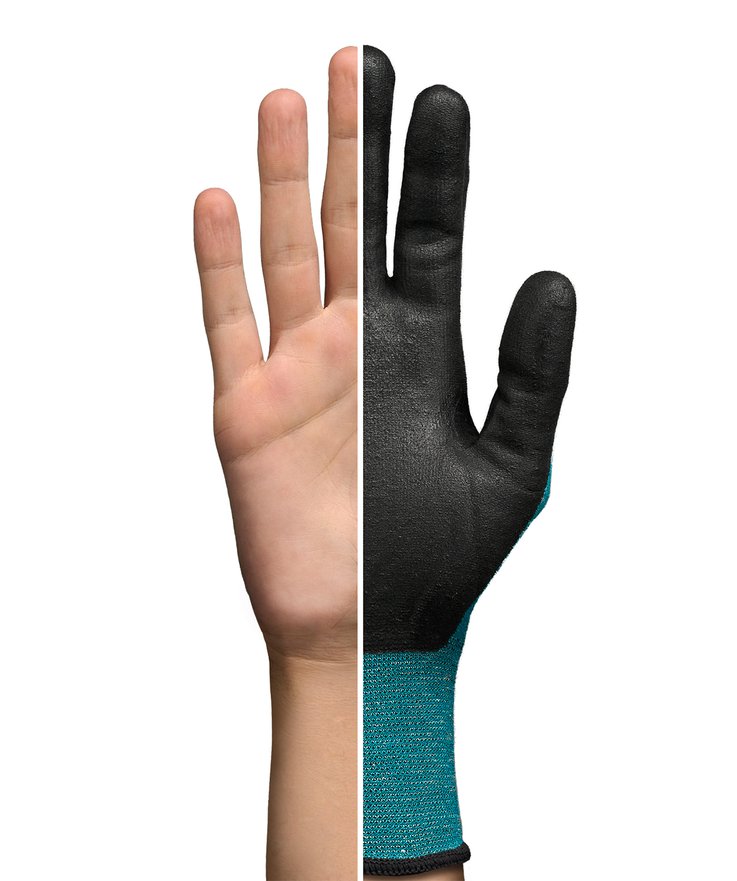

3D ErgoFlex Technology

Adaptable? Of course. Our gloves fit perfectly like they were made for you.

Every hand is different — but uvex safety gloves fit them all perfectly. Almost as if they were tailor-made for you. The secret behind the perfect fit is the innovative 3D ErgoFlex technology from uvex in conjunction with adaptive fit yarn technology: First, the gloves are pre-formed on special 3D ergonomic shapes based on nature — down to the smallest detail.

uvex has developed innovative 3D ErgoFlex Technology: Because every hand is different.

The high-tech yarns developed by uvex are key to the perfect fit: Body heat and movement causes them to twist and adapt gently to the individual shape of the wearer's hand — like a second skin. Within minutes of putting on the glove, it becomes more and more flexible and comfortable to wear, and then fits perfectly through and through. This ensures unrivalled wearer comfort and greater wearer acceptance, while also making uvex safety gloves the perfect fit for a wide range of needs.

Extended LifeSpan Technology

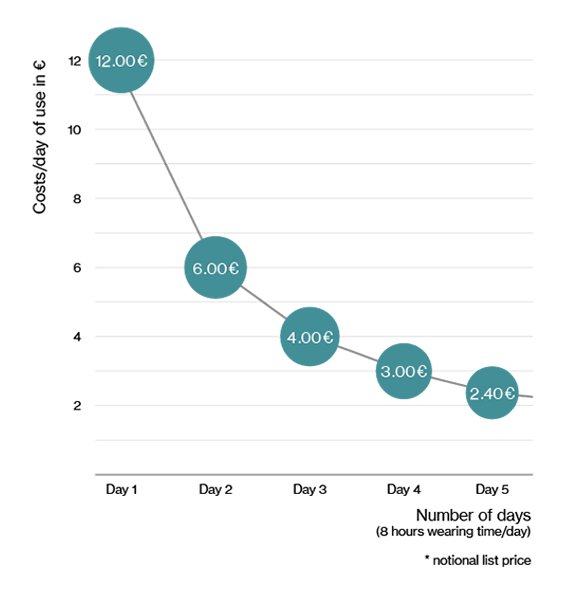

Our gloves last much longer. This makes them unbeatable value for money.

Safety gloves from uvex not only offer top-class quality, but are among the most cost-effective gloves on the market. Why? Because they last significantly longer compared to similar models thanks to Extended LifeSpan technology. The nitrile cross-linking systems developed entirely in-house by uvex and the unique coating process significantly increase the service life of the gloves.

Extended material technology

for longer service life and greater cost-effectiveness

In this unique production process, the nitrile coating penetrates into the fibre, forming an extremely stable compound of nitrile coating and textile. The abrasion resistance significantly exceeds the EN 388 standard and far surpasses other gloves. In most uvex customer tests, a significantly longer wearing time was achieved, especially during extremely demanding applications. This makes uvex safety gloves especially cost-effective and, because less waste is produced, also more sustainable. That's just typical uvex.

Market standard

After the sandpaper test*, the standard gloves shows visible abrasion on the coating and material after just a few movements over the surface.

Extended LifeSpan Technology

Extended LifeSpan Technology ensures that the coating and material of the uvex glove remain intact in the same sandpaper test* even after several repetitions.

* internal application test to determine abrasion resistance.

Safety gloves from uvex not only offer top-class quality, but are among the most cost-effective gloves on the market.

Why?

Because they last significantly longer compared to similar models thanks to Extended LifeSpan Technology.

uvex CrossLinking Technology

We make our coatings in-house. This makes all the difference.

When it comes to coating safety gloves, there's only one thing uvex trusts: its own expertise. The self-developed production process with a worldwide unique, allergen-free recipe for the uXT cross-linking systems is purely water-based and free from harmful chemicals. This creates a unique coating that is both extremely robust and highly flexible at the same time — and also offers perfect grip.

Extremely robust and super-flexible uXT coatings

with best grip properties

Whether in oily, wet or dry conditions, uvex safety gloves are at the highest level when it comes to grip and sensitivity. The fact that uXT technology does not use the usual accelerators with allergenic potential is felt not only by the wearer, but also by the environment: The production process is much more sustainable. With uXT technology, uvex offers a coating that simply does more. Extremely durable, free from allergens, highly flexible and offering the best grip. 100% "made by uvex".

Superior structure

Compared to the market standard, uvex safety gloves are particularly soft and flexible, as weil as extremely robust.

True DermaSafe Technology

With every single pair of our gloves, we strive to achieve perfect quality with no harmful chemicals.

The guiding principle at uvex is protecting people. This is why all of our safety gloves are subjected to extensive testing by independent laboratories and institutes. For skin compatibility, freedom from harmful substances and much more. This especially applies to high health standards: uvex analyses its gloves for 200 classes of hazardous substance — more than twice the number of chemicals required by the REACH Regulation.

Optimal health standards and clinical tests

for ideal skin compatibility

The excellent skin compatibility of the safety gloves has been confirmed by the independent proDERM Institute in Hamburg: A 2×24-hour test with 30 test subjects, some of whom had pre-existing allergies, proved that uvex safety gloves have no allergenic potential and are particularly skin-friendly. No surprise at all: uvex safety gloves have water-based, solvent-free coatings and do not require any allergenic accelerators. You can rely 100% on uvex: We know what goes into it.

uvex patented finger tear-off technology

The safest protection glove for rotating tools

Thanks to the patented uvex finger tear-off technology, you no longer have to compromise when working with sharp-edged parts or rotating tools and machinery.

No hand injuries from sharp edges or from glove fingers becoming caught in rotating tools

Thanks to the integrated break sections, the uvex gloves with finger tear-off technology tear off before that point.

All uvex gloves with finger tear-off technology have reduced tear resistance in the finger area due to the integration of seamless break sections. This patented feature reduces the risk of hand injuries when using manually operated screwdrivers.