designed to recycle

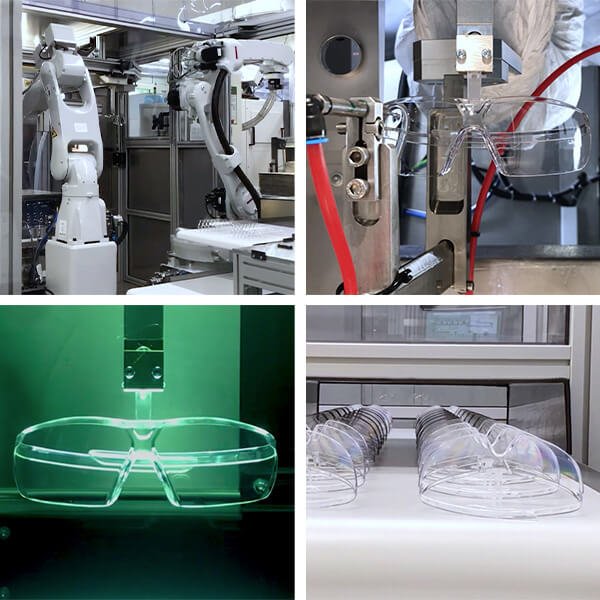

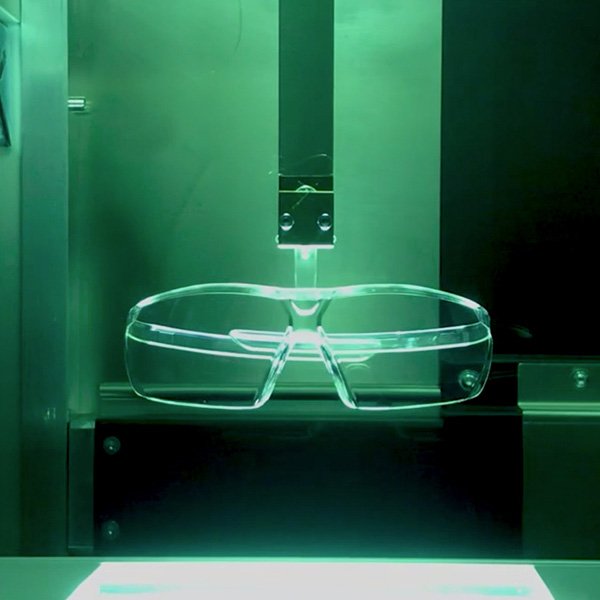

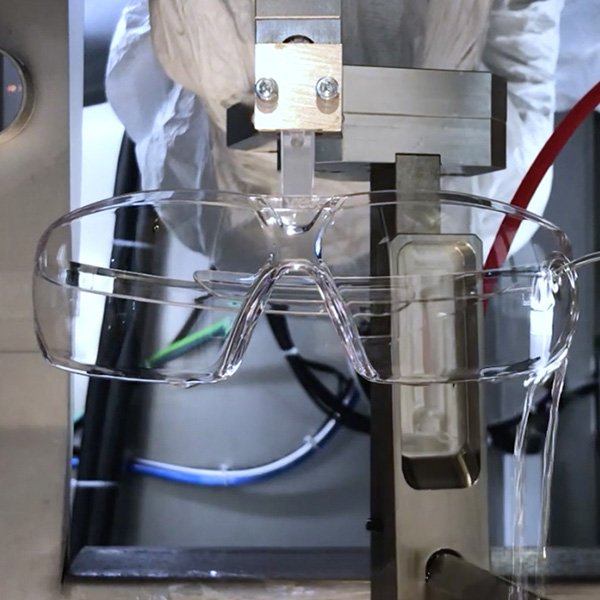

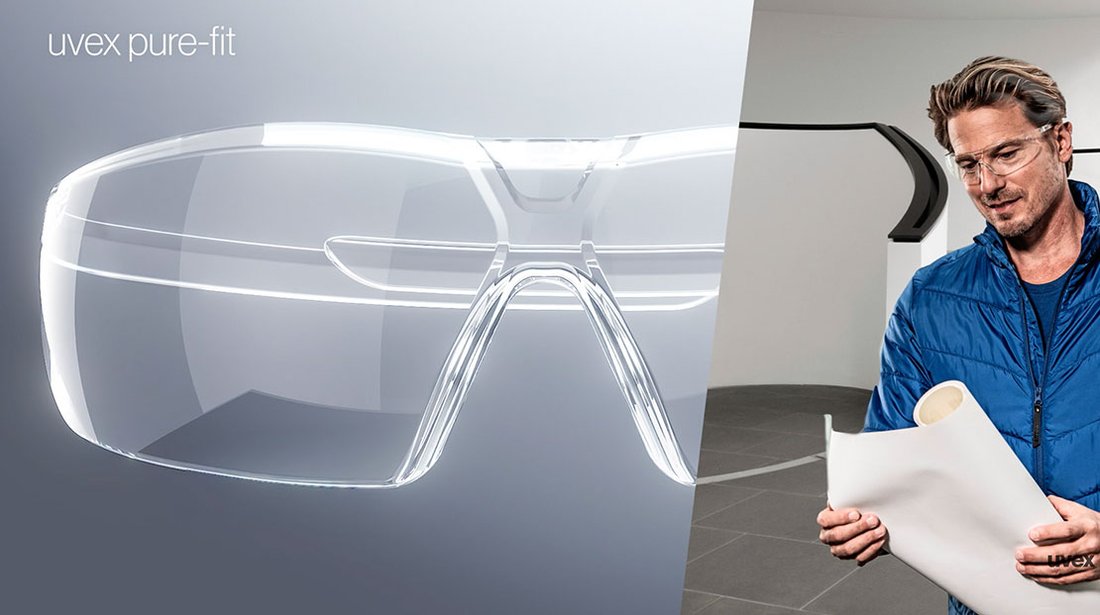

Thanks to an innovative new production technology, the uvex pure-fit can be manufactured fully automatically from just one material without the need for additional assembly. It is made entirely of polycarbonate and is therefore 100% recyclable — just like the product packaging.

This makes the uvex pure-fit an extremely sustainable solution.

reduced to the max

Not just innovative but comfortable too: These safety spectacles are extremely lightweight. The flexible side arms fit perfectly to many head shapes and ensure a secure hold. The uvex pure-fit is available in two different versions: uncoated and, of course, coated with the proven uvex supravision coating technology.

For perfect vision without compromise: The innovative, frameless lens design ensures a wide, unrestricted field of vision in various situations.

protecting planet

innovative technologies

Consistently going one step further: The uvex pure-fit safety spectacles made of single-grade material are manufactured in a fully automated production process using only a single injection moulding machine. This has reduced CO2 emissions by around 50%. We are therefore combining innovative technology with sustainable actions all at the highest level of quality, made in Germany.

sustainable production

For a clean environment: The 100% recyclable uvex pure-fit does not need to be assembled and is packaged directly at the production plant – this helps to cut CO2emissions in logistics. Using new packaging units, printed labels and more compact operating instruction manuals, we have reduced the amount of packaging materials by more than half.