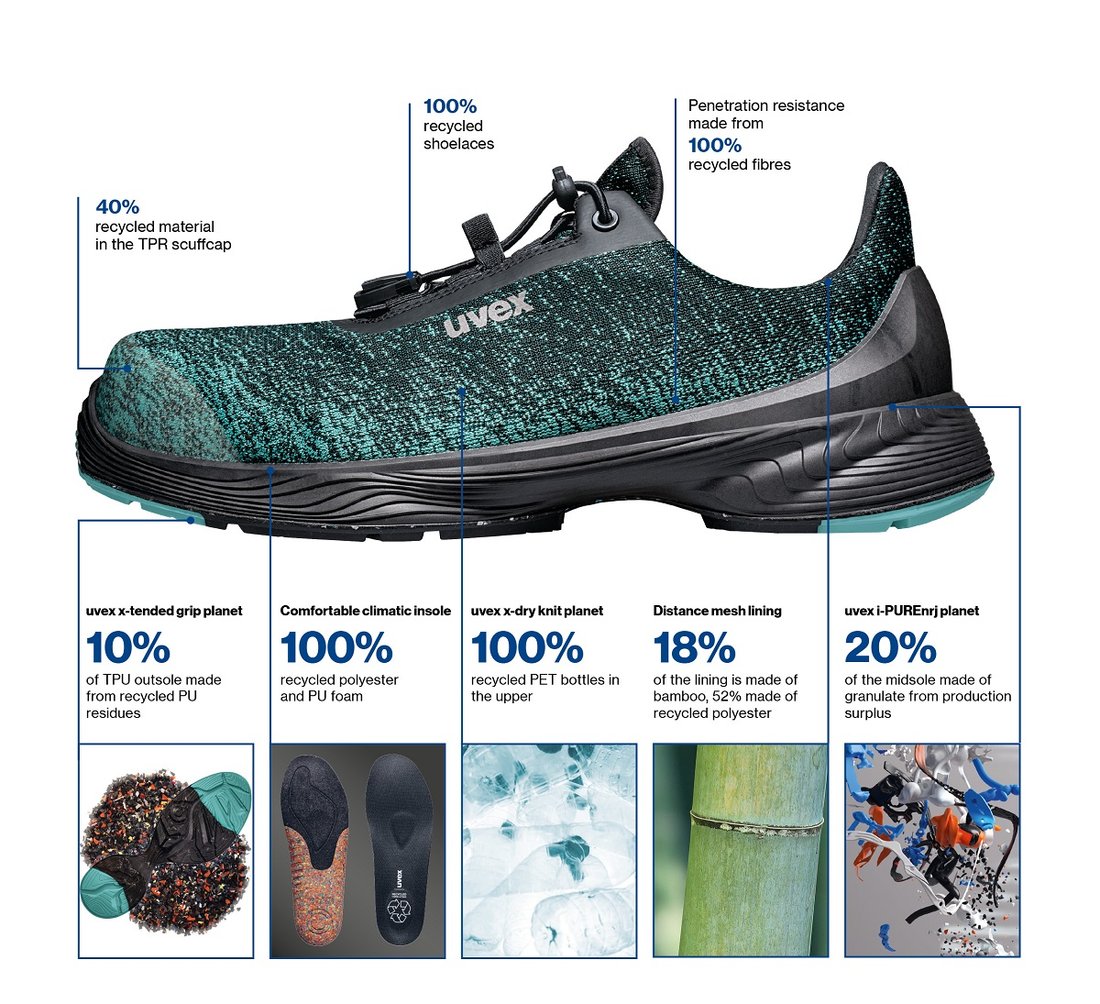

uvex 1 G2 planet – sustainable safety shoe made from recycled materials

Recycled down to the last crumb: From the outer shoe material to the sole, the new uvex 1 G2 planet offers both sustainability and performance in the same shoe.The injected polyurethane midsole contains up to 20% granulate made using PU waste from our production processes. With this safety shoe, you can protect both yourself and the planet.

Components of uvex 1 G2 planet in detail:

For the first time, we have calculated the CO2 footprint for a uvex safety shoe. This tells us how much CO2 is emitted during the production of a pair. To calculate this, we measured the emissions from the raw materials to the first use**.

The result is that the CO2 footprint of the uvex 1 G2 planet is 6.9 kg. This is roughly equivalent to a 35 km car journey. By using recycled and bio-based materials, we were able to reduce the CO2 footprint by 1.6 kg or 18.8% compared to our regular uvex 1 G2 (art. no. 68342, CO2 footprint 8.5 kg).

Midsole innovation: i-PUREnrj planet

uvex is the first company to have succeeded in using the direct injection process to integrate granulate made using polyurethane waste from our production processes into the midsole of its safety shoe and to launch the fully certified product on the market. This allows us to save on raw materials and to return the PU waste we produce to the shoe production cycle without compromising the performance of our i-PUREnrj technology, which provides cushioning and energy return across the entire sole of the foot, helping reduce wearer fatigue.

uvex i-PUREnrj Technology

Shock-absorbing. Stabilising. Energy-returning.

- outstanding shock absorption and energy return

- foamed heel basket provides excellent stability and reduces the risk of injury

The production in Italy, which is one of the most modern production facilities for safety shoes in Europe, ensures efficient, resource-saving production and short distances from manufacturer to user.

Our PU waste recycling cycle

Step 1

Removing the PU waste from the finished shoe

Step 2

Reducing the PU waste to granulate

Step 3

Absorbing and mixing the granulate into the PU compound

Step 4

Direct injection soling using PU material incl. granulate

Der uvex 1 G2 planet

More information

Calculations based on Sima Pro 9.2.0.1, ecoinvent 3.6 database | *calculated in accordance with DIN EN ISO 14021:2016 | **the end-of-life emissions depend on the method of disposal.