Cut protection gloves from uvex

prevent cuts

Injuries caused by cuts or stabs on fingertips, fingers, the back of the hand or the palm of the hand can quickly become a serious danger when handling sharp (edged) equipment or materials in many industries. This is why hand protection through certified and cut-resistant safety gloves is so important. At uvex, you can buy high-quality cut protection gloves that comply with the applicable legal standards. Get an overview of the areas of application, protective functions, protection classes and materials of the cut protection gloves from uvex.

Find the perfect work gloves for your workplace needs!

FILTER

- Chemical protection gloves

- Cold protection gloves

- Cut protection gloves

- Heat-resistant gloves

- Impact gloves

- 3D ErgoFlex Technology

- Bamboo TwinFlex® technology

- Extended LifeSpan Technology

- Touchscreen capability

- True DermaSafe Technology

- Protects against cutting injuries

- Protects against grazes

- Protects against impact injuries

- Protects against lacerations

- Protects against pinching

- EN 388:2016

- EN ISO 21420:2020/EN 388:2016 + A1:2018/EN 407:2020

- EN ISO 21420:2020/EN 388:2016 + A1:2018/EN 407:2020/EN 16350:2014

- EN ISO 21420:2020/EN 388:2016 + A1:2018/EN ISO 374-1:2016 + A1:2018

- EN 420:2003 + A1:2009/EN 388:2016 + A1:2018/EN 407:2020

When are cut protection gloves advisable in the workplace?

Whether cut-resistant safety gloves are necessary at your workplace can be seen from the risk assessment. This is a safety check by a competent person in the service of occupational health and safety. It takes stock of hazard risks, injury risks and existing hazards at each workplace and derives necessary safety and occupational health and safety measures from this. The employer is obliged to commission this risk assessment.

A possible safety measure can be the use of personal protective equipment such as work trousers, work jackets, safety shoes, safety helmets or even cut-resistant gloves.

What standards are cut protection gloves subject to?

In HexArmor's American product series, the cut protection gloves comply with the American standard ANSI/ISEA 105-2016. The uvex product series are certified according to the European standard EN 388:2016.

In a comparison of the two regulations, the American standard distinguishes a total of nine cut protection levels (A1-A9). The European standard distinguishes between six levels of cut protection (A-F). A detailed comparison of the two standards in terms of impact protection, stab protection and cut protection classes for gloves can be found in our blog article "Cut protection standards ANSI/ISEA 105-2016 and EN 388-2016 compared". For more information about the HexArmor® cut protection gloves in Europe, please visit our website.

In which activities do cut protection gloves protect?

As mentioned, cut protection gloves are used in very different industries; but especially where sharp knives, cutting tools or sharp-edged objects are used. Here is a selection:

If you work in glass or metal processing, you might be interested in the practical report Firm, firmer, textreme cut – cut protection made by uvex and the uvex technologies for very high cut protection for safety gloves.

Cut protection classes for uvex gloves

According to the American standard ANSI/ISEA 105-2016, the degree of cut protection is divided into cut protection levels A1 to A9, while the European standard EN 388-2016 distinguishes between classes A to F, which roughly correspond to cut protection levels A1 to A6.

This information depends on whether the cut protection glove comes from a HexArmor® product family or from uvex directly. Cut protection levels are measured in Newtons and grams. The gram specification is about the weight that is needed to cut through the material at 20 millimeters of blade travel.

| Amerik. Cut protection level | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 |

| europ. Protection class | A | B | C | D | E | F | |||

| Newton | ≥ 2 | ≥ 5 | ≥ 10 | ≥ 15 | ≥ 22 | ≥ 30 | |||

| Weight (g) | ≥ 200 | ≥ 500 | ≥ 1.000 | ≥ 1.500 | ≥ 2.200 | ≥ 3.000 | ≥ 4.000 | ≥ 5.000 | ≥ 6.000 |

What other protective functions do uvex cut protection gloves offer?

The cut protection is supplemented by other protective functions in uvex work gloves. This is what makes the cut-resistant glove really effective in construction work, in machine and tool construction as well as in other branches of industry. The suitable model can thus cover the basic protection needs at your workplace.

Stab protection

certified according to ANSI/ISEA 105 standard

impact protection

according to ANSI/ISEA 138

Chemical protection

according to EN 374-1:2016

Cold protection

according to EN 511

Protection against heat and heat

according to EN 407

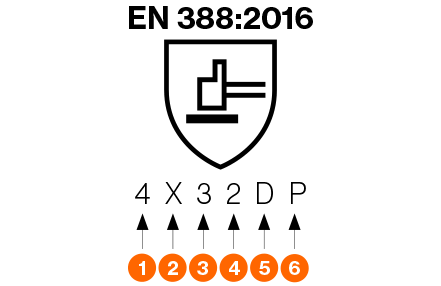

In addition, the work gloves and cut protection gloves from uvex offer further protective functions. A selection of them can be seen on this logo, which is usually worn by cut-resistant gloves according to EN 388:2016:

- Abrasion resistance (0 to 4)

- Coup test cut resistance (0 to 5; X=not applicable or not tested)

- Tear resistance (0 to 4)

- Puncture resistance (0 to 4)

- Cut resistance in accordance with ISO (A to F)

- Impact protection (P if passed)

What materials and technologies does uvex use for the cut protection gloves?

In order to achieve the above-mentioned protective functions, uvex works with various material combinations and material technologies. The focus is primarily on hand protection, but the fit and comfort of the cut-resistant gloves are also relevant. This list gives you an insight into uvex's innovative materials and technologies:

Kevlar is an extremely strong synthetic para-aramid fiber that combines heat insulation and resistance (up to + 250°C), cut resistance and abrasion resistance.

How can I clean my cut-resistant gloves?

Since uvex safety gloves (cut-resistant) are made of different material combinations, you should definitely follow the care instructions when cleaning. Gloves that have already been damaged should always be replaced, otherwise reliable cut protection can no longer be guaranteed.

What role does sustainability play in the production of cut protection gloves?

uvex aligns its actions with the motto "protecting people" and, consequently, also with the motto "protecting planet" in order to take responsibility for people, society and the environment:

"With protecting planet, we have created a label that offers maximum transparency and information about our sustainability activities: from resource-saving products and innovative measures in our own plants to social commitment and social projects."

– Managing Director Michael Winter

"Protecting Planet" can be seen in practice, among other things, in

environmentally friendly packaging and the reduction of cardboard material

Materials made from organic and plant substances

the use of recycled materials

Green electricity and electricity-saving measures

the reduction of harmful substances

the Manufacturing Long-Term Products

We have presented other of uvex's sustainability activities for you under protecting planet. In addition, we at uvex safety gloves GmbH pay close attention to sustainability and have the certificate of the international environmental management standard ISO 14001. This certificate is awarded to companies that demonstrably work continuously to improve environmental protection in their company. In this respect, uvex safety gloves GmbH is so far the first company in Europe to receive this demanding certification.

What size cut protection gloves will fit me?

uvex produces its cut-resistant work gloves for hands of different sizes in different sizes. Measure the circumference and length of your hands to determine your size. Instructions for measuring can be found on the page Size Chart.

Or use our size guide to print them out. Here you can quickly and easily determine the right glove size for your hand width and length with a sheet of paper.

| Größe | Handumfang (mm) | Länge (mm) |

|---|---|---|

| 6 | 152 | 160 |

| 7 | 178 | 171 |

| 8 | 203 | 182 |

| 9 | 229 | 192 |

| 10 | 254 | 204 |

| 11 | 279 | 215 |

When searching for products, make sure that the cut-resistant glove model is also available in your hand size.

Buy cut protection gloves from uvex online

Find the optimal cut protection gloves that combine all the necessary protective functions for the requirements of your workplace at uvex! To search for hand protection, use our extensive filter options (especially "product type" for the protective functions) or our safety glove advisor. With this, you can display a suitable product range according to the type of requirement and the working environment. The page How do I find the right protective glove? will guide you through the selection options. If you have any questions, please feel free to contact our hand protection experts, who can be reached by e-mail at gloves@uvex.de or by phone at +49 4131 9502-0.