uvex occupational safety equipment for paint, plastics and clean room applications

In order to meet the high requirements of customers, products must meet the highest quality standards. Paint compatibility, the guaranteed absence of lint and product protection all play an important role in this.

uvex has made ‘protecting people’ its own mission, as well as focussing on production processes in parallel. Substances that interfere with wetting agents are simply not an option in your production facility and for your employees’ protective equipment, which is why uvex has already taken this into account in its manufacturing process.

To ensure a perfect finish in your production, uvex uses materials and substances in the production of its personal protective equipment that make it safe to use in the painting process. As a provider of head-to-toe PPE, we can therefore produce tailored equipment that fulfils your highest quality requirements for vehicles and employees. Our material experts work closely with the laboratories of major automotive manufacturers to monitor test procedures (for substances that impair paint coatings) and to prevent distorted finishes.

Not only do unwanted substances jeopardise a perfect paint finish on your vehicles, but so can fibres and lint that can come loose from employees’ clothing. The same applies to lots of clean rooms, in which PPE must protect people and the respective product. uvex uses shirts made from Tencel especially for this purpose; Tencel is a fibre taken from the pulp of natural eucalyptus wood from sustainably managed forests and impresses with its high moisture-absorbing capability and its lint-free properties.

With the Glove Expert, you can quickly and easily get expert support in choosing the right safety gloves and protective equipment for handling the hazardous substances that you work with. In addition to standard permeation lists, you can create individual permeation lists yourself. Alongside proudly producing a variety of gloves in Germany, our production site in Lüneburg has its own laboratory that can analyse the hazardous substances that you work with and recommend gloves to meet your needs.

Respiratory protection advisor

The quickest way to find the respirator that perfectly meets your needs.

Experience the whole world of uvex live

You can meet us at these trade fairs. We look forward to seeing you.

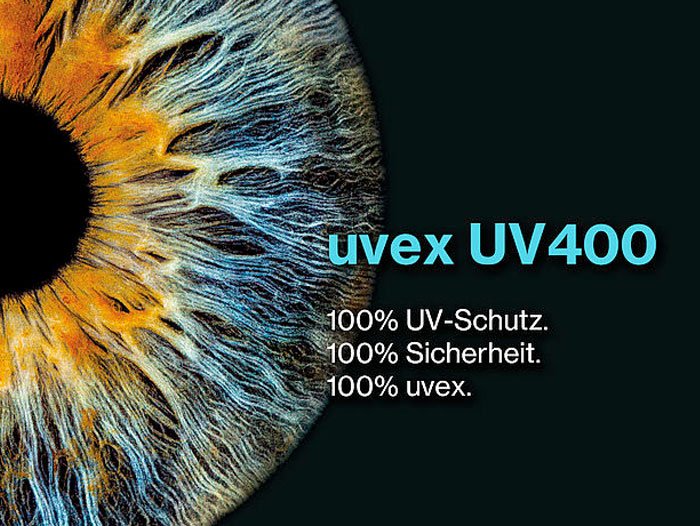

Eye protection for paint, plastics and clean room applications

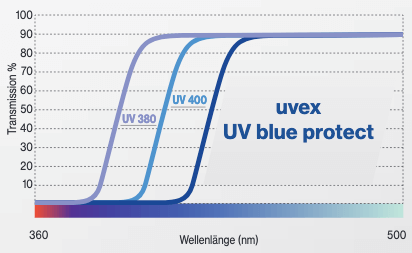

UV400 vs. UV380

The WHO recommends UV protection up to 400 nm. For uvex, this has always been a given.

Hand protection for paint, plastics and clean room applications

Foot protection for paint, plastics and clean room applications

Shoe size finder

The uvex shoe size finder app makes it particularly easy to measure your feet and to find the shoe size and width you need.

Head protection for paint, plastics and clean room applications

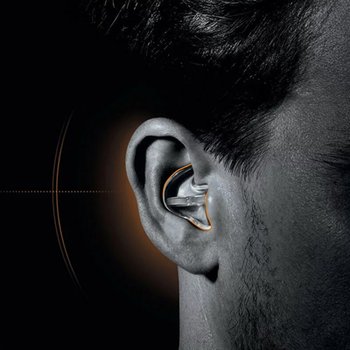

Hearing protection for paint, plastics and clean room applications

Using earplugs correctly

You will only benefit from the full protective effect of your hearing protection if you insert it correctly and clean reusable earplugs properly.

Respiratory protection for paint, plastics and clean room applications

Respiratory protection advisor

The quickest way to find the respirator that perfectly meets your needs.

Protective clothing for paint, plastics and clean room applications

Prescription safety spectacles and VDU spectacles for paint, plastics and clean room applications

uvex RX cd - comfort & design

uvex RX – plastic frames

CR39

- Also known as: plastic

- Not suitable for safety spectacles unless modified, as the tensile strength is otherwise too low. The middle of the lens must be thicker in order to meet the requirements for tensile strength.

- organic, lightweight material

- excellent optical image reproduction properties, even for high prescriptions

- suitable for working with chemicals and paints/varnishes

- good scratch resistance due to hard coating (optional)

- mechanical strength, class “S” (ball drop test)

Trivex™

- organic material with high tensile strength

- lightweight, also suitable for high prescriptions

- excellent optical image reproduction properties, even for high prescriptions

- excellent resistance to cleaning agents, oils and cosmetics

- good scratch resistance

- best all-round lens material

- mechanical strength, class “F” (45 m/sec)

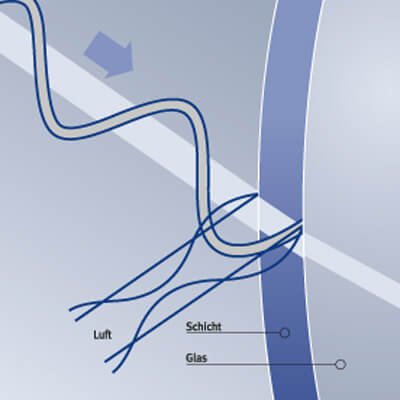

Anti-reflective coating

Anti-reflective coating is a layer applied to the inside and outside of lenses using vapour deposition. It significantly reduces reflections on the surfaces. It offers a cosmetic advantage and increases light transmission.

Three types of coating are available:

- Normal anti-reflective coating

- Multi anti-reflective coating

- Super anti-reflective coating

UV blue protect

A special absorber has been added to the lens material that completely filters out UV rays and reduces the blue light content.

- The lenses absorb UV radiation up to 400 nm at 100%, filter short-wave blue light up to 410 nm almost completely and reduce the spectrum from 410 nm to 420 nm by 86%.

- uvex UV blue protect lenses enhance contrast and effectively prevent signs of fatigue and age-related macular degeneration (AMD).

- The mechanical strength of the lenses is guaranteed – clear lenses with UV blue protect are marked 2C-1.2.

- UV blue protect is optionally available for polycarbonate (PC) lenses and HI 1.67.

Our service for optimal protection

Individual eye protection with uvex VDU spectacles and uvex prescription safety spectacles.

Otoplastics for paint, plastics and clean room applications

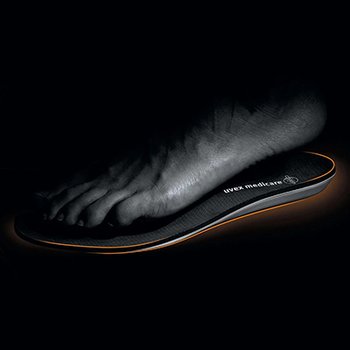

Medicare for paint, plastics and clean room applications

Certified safety shoe insoles from uvex medicare

Everything you need to know about insoles at a glance!

(German only)

Consultation appointment with our uvex automotive experts

Are you interested in our uvex occupational safety equipment for the automotive industry and would like to discuss questions and possible conditions? Our uvex automotive experts will be happy to help. Submit a request via our online contact form and we will send you more information.